铝及铝合金是具有轻质、良好延展性和抗腐蚀性等优点的金属[1-2]。 激光粉末床熔化(laser powder bed fusion,LPBF)是金属材料增材制造的一种主要技术[3-6],具有近净成形、生产效率高、节省材料等优势[7-10]。近年来采用激光粉末床熔化技术制备铝及铝合金逐渐成为学者们关注的热点, 然而材料的自身特性限制了该技术的进一步发展。 一方面,在通常使用的波长为1 064 nm 或1 070 nm 的激光下[11],铝合金激光吸收率非常低(10%);另一方面,铝的高热导率(237 W/(m·K))[12]会加快打印过程中加热和冷却的速度。 因此,如何避免铝及铝合金的激光粉末床熔化打印态样品普遍的粗大柱状晶组织,并进一步减少热裂纹缺陷的产生是亟待解决的难点[13-18]。

铝基复合材料(aluminum matrix composites,AMC)是解决铝及铝合金激光粉末床熔化打印难点的思路和方案。 复合材料由两个或两个以上物理和化学性质不同的部分组成,包括连续的基体和不连续的增强相[19-20]。 通过向铝合金引入TiB2、石墨烯、TiC 等纳米增强体[21-24],能够显著细化打印态样品的晶粒,改善铝合金在打印过程中的热裂纹问题[25-29]。并且铝基复合材料综合了铝、铝合金的优点以及纳米增强体高强度、高弹性模量的特点[30-32],具有优异的比强度、比刚度、耐磨性和低热膨胀系数,在航空航天、军工、交通运输等领域得到了广泛应用[33-36]。

本文总结分析了TiB2、石墨烯、TiC 纳米增强体对铝合金打印态样品的晶粒形态、晶粒尺寸、相对密度、可打印性和力学性能的影响,对比了现有主流的纳米增强体类型对打印态铝合金力学性能的影响,并提出了该研究领域未来的发展趋势。

1 TiB2 增强

TiB2 具有高熔点、高硬度、良好润湿性、与铝基体共格性良好等优点[35,37]。TiB2 纳米颗粒的引入方式主要包含两大类:原位自生和外加法(球磨法、机械搅拌法等)[38-39]。 在研究之初, 铸造是用于制备TiB2纳米颗粒增强铝基复合材料的主流方法之一, 包括搅拌铸造、挤压铸造等[40-42],也有学者对其进行过半固态成形的研究[43]。 近年来由于增材制造技术的迅速发展,对TiB2 纳米颗粒增强铝基复合材料激光粉末床熔化加工的研究不断增多。引入TiB2 纳米颗粒能够改变铝合金打印态样品的晶粒形态和尺寸,起到改善铝合金打印态样品相对密度、可打印性、力学性能等作用。

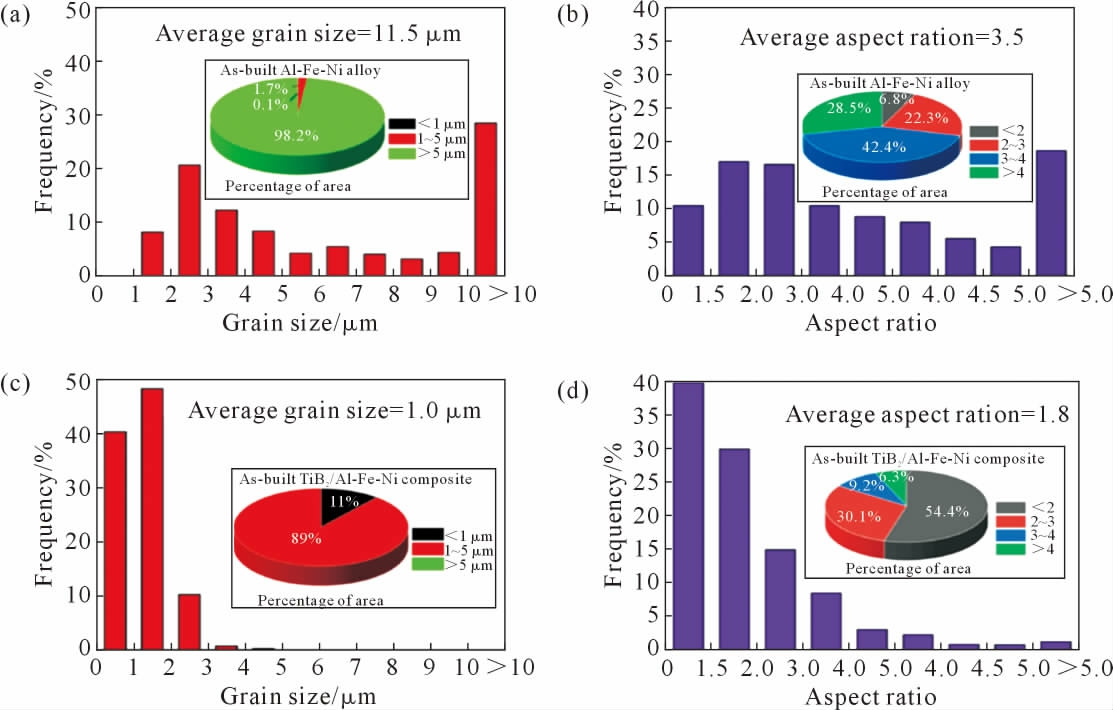

在铝合金打印态样品晶粒形态和尺寸的改变方面,上海交通大学Guo 等[44]采用原位自生和气雾化法制备了6%TiB2/AlSi10Mg(质量分数)复合粉末,使用AlSi10Mg 粉末作为对照材料, 分别对两种粉末进行了激光粉末床熔化单轨扫描试验。 借助EBSD表征手段,发现TiB2 纳米颗粒的引入会导致柱状晶含量减少而等轴晶含量增多,起到了细化晶粒的作用。上海交通大学Ding 等[45]通过原位自生制备了2%TiB2/Al-1.75%Fe-1.25%Ni(质量分数)复合粉末,并采用激光粉末床熔化技术打印样品。 采用EBSD 手段进行表征并分析了晶粒尺寸的统计结果,从图1~2可以看出,与Al-Fe-Ni 打印态样品相比,TiB2/Al-Fe-Ni 打印态样品的组织由粗大柱状晶转变为细小等轴晶,平均晶粒尺寸和晶粒纵横比分别减小91%和49%。上海交通大学Sun 等[46]采用原位自生和气雾化法制备了2%TiB2/Al4Cu1.6Mg0.6Mn(质量分数)的复合粉末,应用激光粉末床熔化技术分别打印出TiB2/Al4Cu-1.6Mg0.6Mn(A2T)和Al4Cu1.6Mg0.6Mn(A0T)样品。借助EBSD 表征手段观察到沿着打印方向,与A0T打印态样品相比,A2T 打印态样品呈现出以细等轴晶为主加少量柱状晶的组织, 平均晶粒尺寸减小87%。 TiB2 纳米颗粒的引入使得铝合金的晶粒形态由柱状晶向等轴晶转变,细化了晶粒尺寸。

图1 Al-Fe-Ni 和TiB2/Al-Fe-Ni 打印态样品EBSD 结果:(a)Al-Fe-Ni 的band contrast 图,(b)Al-Fe-Ni 的IPF 图,(c)TiB2/Al-Fe-Ni

的IPF 图,(d)TiB2/Al-Fe-Ni 的TiB2 相分布图[45]

Fig.1 EBSD results of the as-built Al-Fe-Ni alloy and TiB2/Al-Fe-Ni composite samples: (a)band contrast map of the Al-Fe-Ni alloy,(b)inverse pole figure(IPF)map of the Al-Fe-Ni alloy,(c)IPF map of the TiB2/Al-Fe-Ni composite,(d)local magnified phase map of

the TiB2/Al-Fe-Ni composite[45]

图2 Al-Fe-Ni 和TiB2/Al-Fe-Ni 打印态样品晶粒尺寸和纵横比分布结果:(a~b)Al-Fe-Ni,(c~d)TiB2/Al-Fe-Ni[45]

Fig.2 Grain size and aspect ratio distribution of the as-built Al-Fe-Ni alloy and TiB2/Al-Fe-Ni composite samples:(a~b)Al-Fe-Ni alloy,(c~d)TiB2/Al-Fe-Ni composite[45]

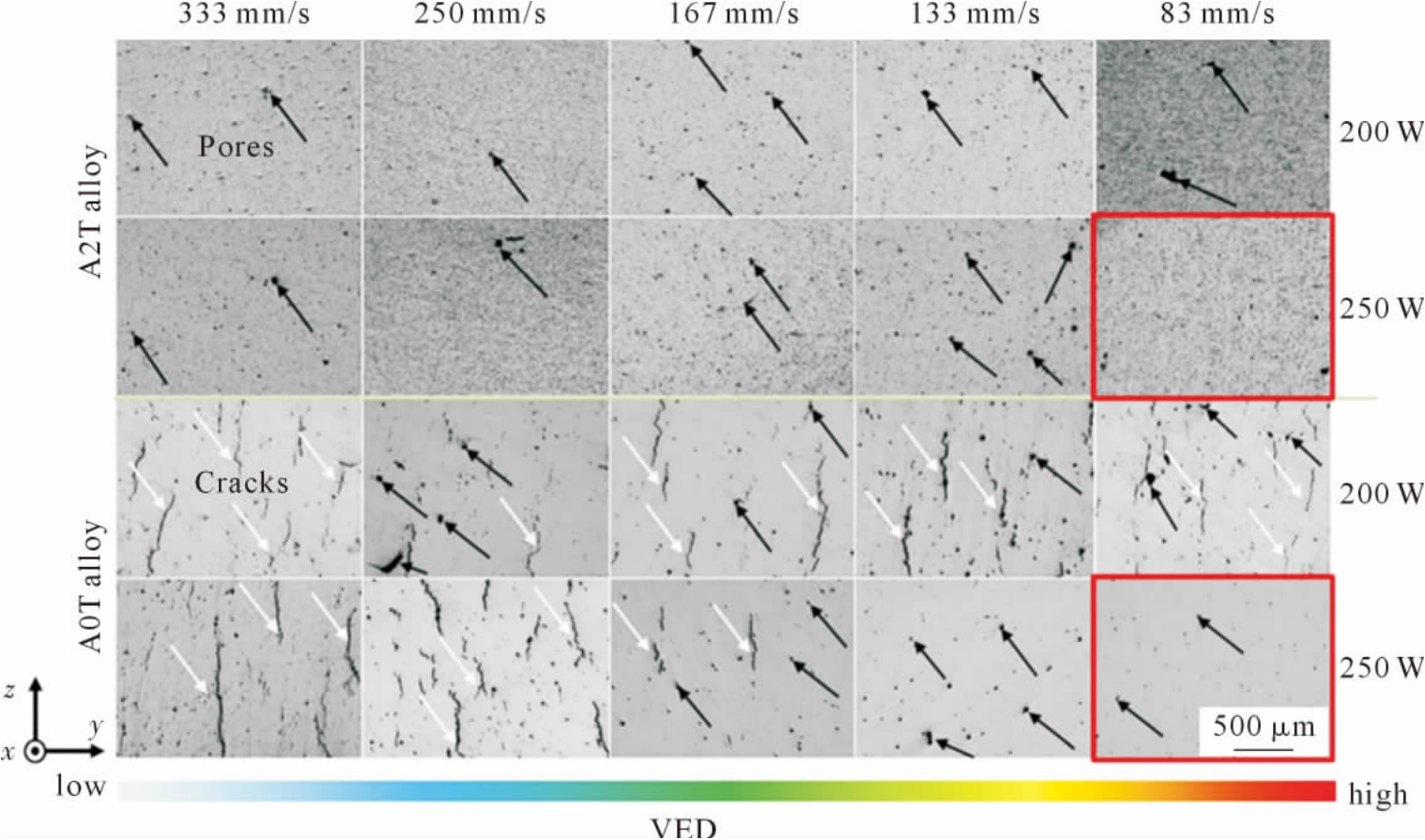

在铝合金打印态样品相对密度和可打印性的改变方面,Ding 等[45]的研究表明,打印态TiB2/Al-Fe-Ni具有更少和更小的圆形孔隙, 打印态TiB2/Al-Fe-Ni的最高相对密度要高于打印态Al-Fe-Ni。 所以,TiB2/Al-Fe-Ni 的打印工艺窗口范围比Al-Fe-Ni 合金更宽,可打印性更高[47]。Sun 等[46]的研究表明,A0T 打印态样品内部存在大量沿着打印方向的裂纹。 如图3所示, 在250 W的激光功率下, 扫描速度为133 mm/s和83 mm/s 时,裂纹基本消失。 而对于A2T 打印态样品,在整个参数范围内,没有明显的裂纹,证明了TiB2/Al4Cu1.6Mg0.6Mn 具有更宽的打印工艺窗口。引入TiB2 改善了Al4Cu1.6Mg0.6Mn合金在打印过程中的热裂纹问题,提高了可打印性。

图3 A2T 和A0T 打印态样品在不同扫描速度和功率下沿着打印方向的OM 图[46]

Fig.3 OM images of the as-built A2T and A0T samples with different scanning speeds and powers along the building direction[46]

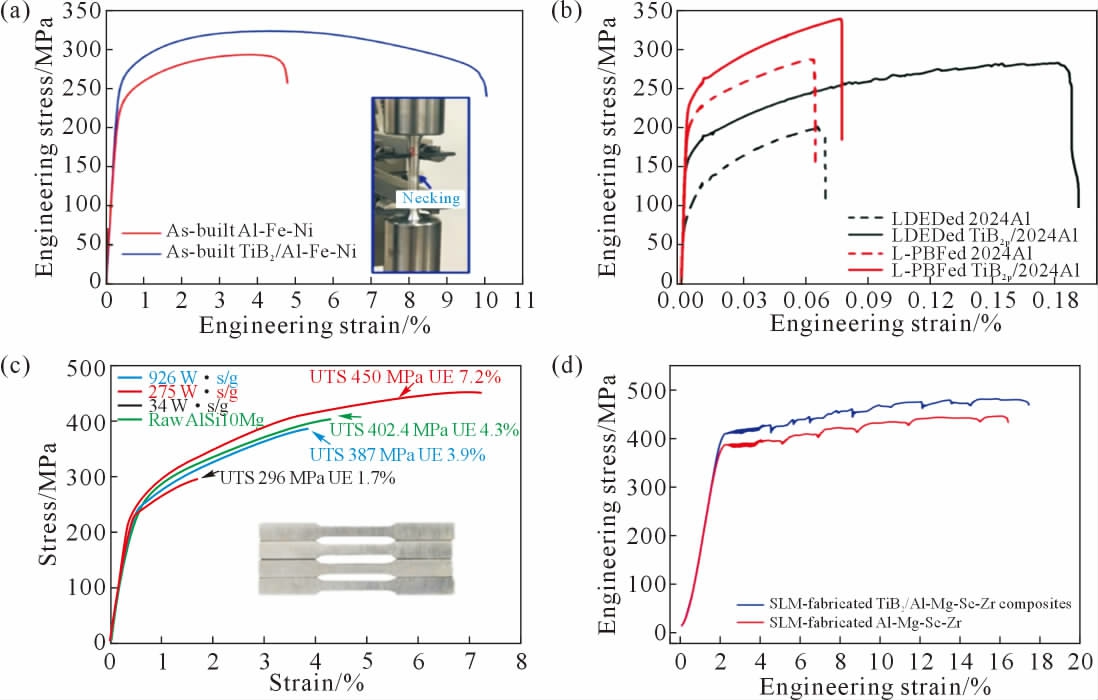

在铝合金打印态样品力学性能的改变方面,Ding 等[45]、西北工业大学Wang 等[48]、南京航空航天大学Wang 等[49]、哈尔滨工业大学Wang 等[14]分别对采用激光粉末床熔化技术打印的TiB2 增强铝基复合材料进行拉伸力学性能实验,结果如图4 所示。图4(a)表明,与Al-Fe-Ni 打印态样品相比,TiB2/Al-Fe-Ni打印态样品的屈服强度、 抗拉强度和伸长率分别提升11.0%、10.6%、129.2%。 图4(b)表明,与打印态2024Al 相比,打印态TiB2/2024Al 的屈服强度、抗拉强度和伸长率分别提升了15.0%、24.4%、77.8%。 图4(c)表明,随着研磨剂量的增加,TiB2/AlSi10Mg 复合材料的抗拉强度和伸长率先升高后降低, 只有275 W·s/g 的研磨剂量使得TiB2/AlSi10Mg 打印态样品的抗拉强度和伸长率高于AlSi10Mg 打印态样品。 所以,采用球磨法制备铝基复合材料粉末时,需要考虑研磨剂量的影响, 选择合理的研磨剂量才能够提升铝合金的力学性能。 图4(d)表明,打印态TiB2/Al-Mg-Sc-Zr 的抗拉强度为(480±2) MPa,伸长率为(15.8±0.7)%,均高于打印态Al-Mg-Sc-Zr。

图4 铝合金和TiB2 增强铝基复合材料打印态样品的工程应力-应变曲线:(a)Al-Fe-Ni 和TiB2/Al-Fe-Ni,(b)2024Al 和TiB2/2024Al,(c)不同研磨剂量制备的TiB2/AlSi10Mg,(d)Al-Mg-Sc-Zr 和TiB2/Al-Mg-Sc-Zr[14,45,48-49]

Fig.4 Engineering stress-strain curves of the as-built Al-alloys and TiB2 reinforced aluminum matrix composites:(a)Al-Fe-Ni alloy and TiB2/Al-Fe-Ni composite,(b)2024Al and TiB2/2024Al composite,(c)TiB2/AlSi10Mg composite samples prepared from milled powder at different milling doses,(d)Al-Mg-Sc-Zr and TiB2/Al-Mg-Sc-Zr[14,45,48-49]

综上所述,学者们对TiB2 纳米颗粒增强铝基复合材料的众多研究成果表明:①引入TiB2 纳米颗粒能够显著细化铝合金打印态样品的晶粒尺寸,促进柱状晶向等轴晶转变;②引入TiB2 纳米颗粒能够改善铝合金在激光粉末床熔化打印过程中出现的热裂纹和孔隙问题, 提升打印态样品的相对密度,拓宽了铝合金的激光粉末床熔化打印工艺窗口,提升了可打印性;③引入TiB2 纳米颗粒能够提升铝合金打印态样品的力学性能。 但目前的研究并没有厘清不同牌号的铝合金,在不同引入方式下引入TiB2 纳米颗粒的含量和激光粉末床熔化打印工艺参数、打印态样品的相对密度、 力学性能之间的复杂耦合关系。 对于不同的铝合金,引入TiB2 纳米颗粒的最优含量以及相对密度和力学性能均能达到较好效果的打印参数仍有待进一步研究。

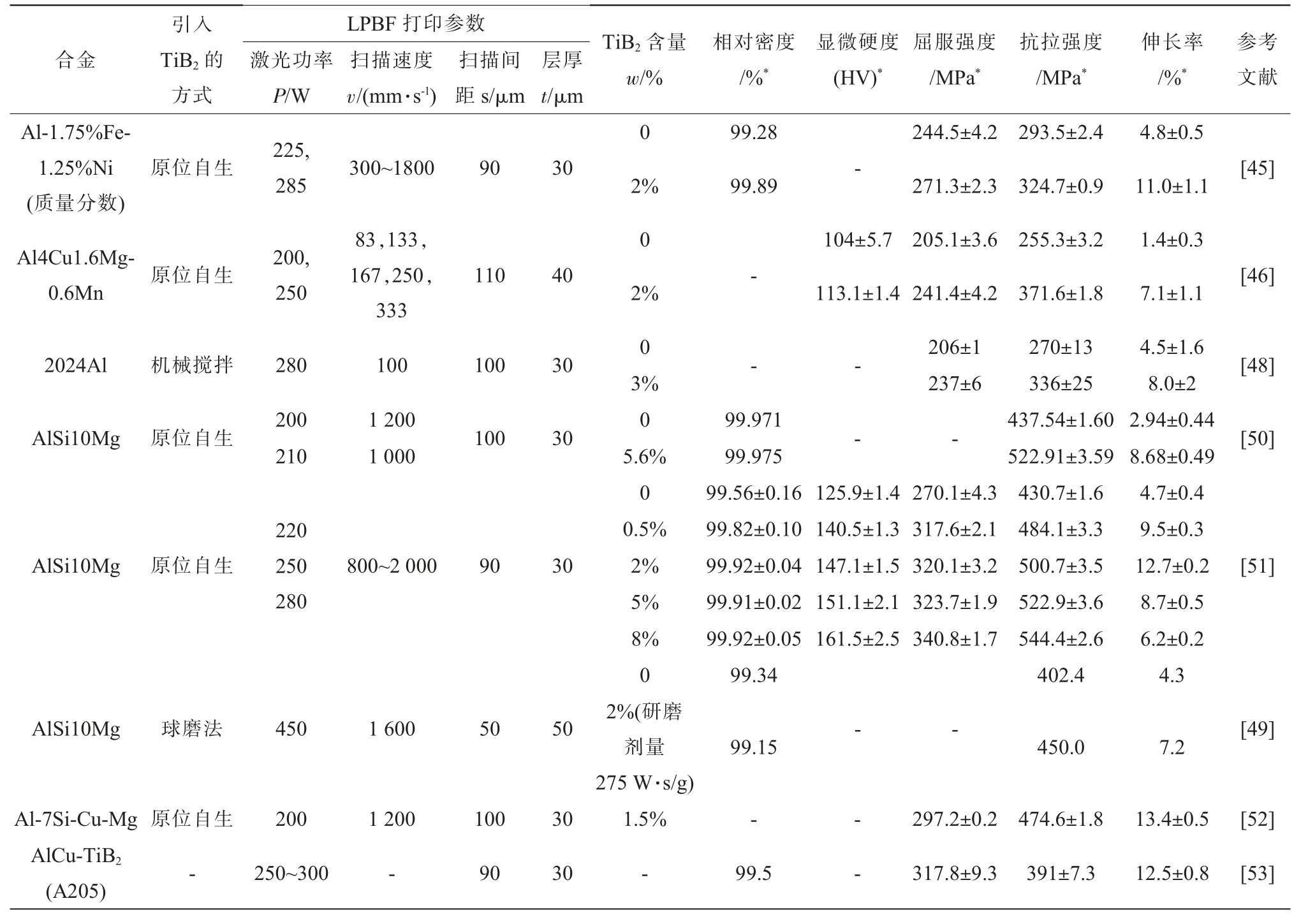

表1为总结的文献中一些TiB2 增强铝基复合材料的相关数据。

表1 TiB2 增强铝基复合材料数据表(“*”表示最大值)

Tab.1 Data sheet of TiB2 reinforced aluminum matrix composites (“*” is maximum)

?

2 石墨烯增强

自2004 年石墨烯成功从石墨中分离出来之后,石墨烯增强铝基复合材料的研究才得以不断由浅入深[54]。石墨烯与铝基体共格性良好,具有良好的导电性、导热性、惰性和表面性能[54],其独特的二维结构造就了优异的力学性能[55-56]。用于制备铝基复合材料的石墨烯包括氧化石墨烯(GO)和非氧化石墨烯(Gr)两大类, 石墨烯的形式主要有石墨烯纳米片(GNPs)和石墨烯粉末两种。 制备石墨烯增强铝基复合材料的粉末主要有两种方法:球磨法和湿化学技术(异质团聚工艺)[54,57]。 在研究之初,挤压铸造是用于制备石墨烯增强铝基复合材料的方法之一[58-59]。 近年来学者们越来越关注采用激光粉末床熔化技术制备石墨烯增强铝基复合材料。引入石墨烯能够改变铝合金的激光吸收率,改变打印态样品的晶粒形态、晶粒尺寸、相对密度、可打印性和力学性能。

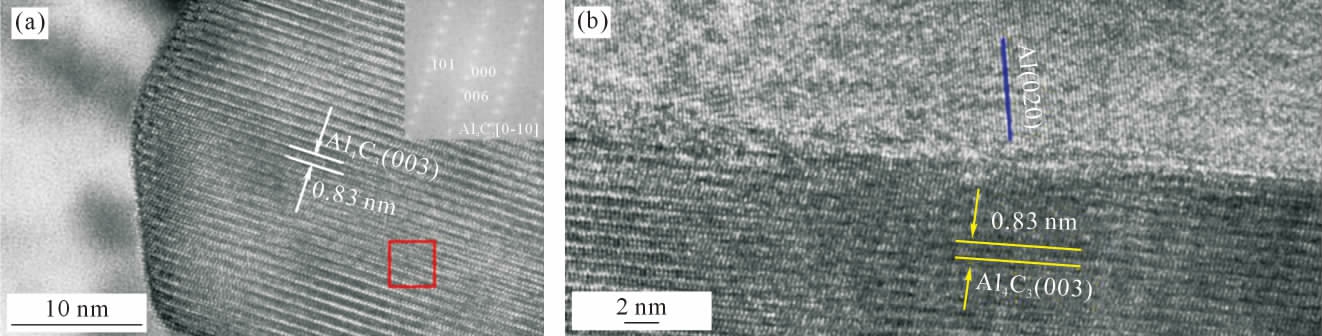

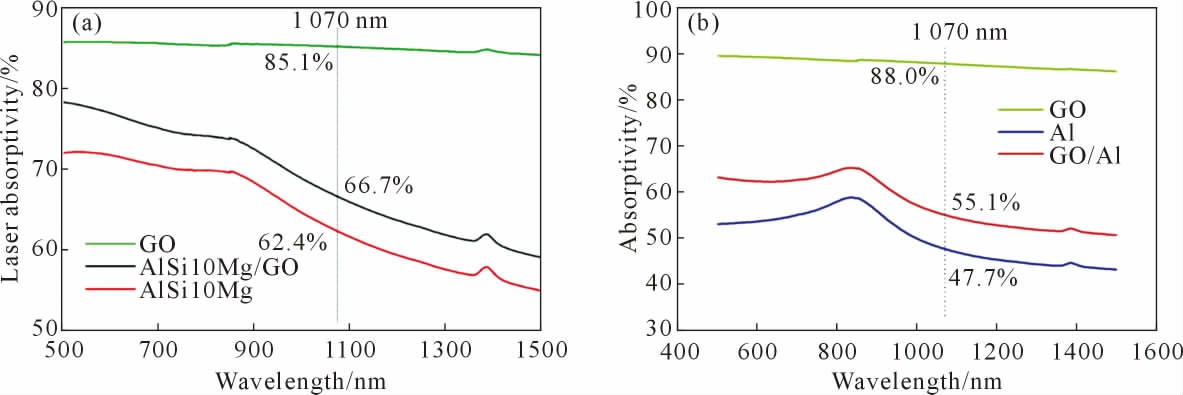

日本东北大学Dong 等[60]通过异质团聚工艺,制备出了质量分数为0.3%氧化石墨烯(GO)/Al-Si10Mg 粉末;Zhou 等[61]采用异质团聚工艺制备出1.0%GO/Al(质量分数)粉末,均使用激光粉末床熔化技术打印样品。GO 中的C 和Al 在打印过程中发生反应,生成Al4C3 强化相。借助TEM 表征手段,从图5(a)可以观察到,Al4C3 纳米相与基体紧密结合;图5(b)显示出清晰的Al4C3-Al 基体界面,该界面结合紧密,无中间化合物或纳米裂纹,表明Al4C3-Al 界面能够进行有效的载荷传递,Al4C3 纳米相具有良好的承载能力,能够对基体起到强化作用。 在铝合金激光吸收率的改变方面,图6 表明,GO 的激光吸收率高于AlSi10Mg 和纯Al,因而引入GO 增强了Al-Si10Mg 和纯Al 的激光吸收率, 使得AlSi10Mg 和纯Al 的可打印性得到提升。

图5 石墨烯增强铝基复合材料打印态样品Al4C3-Al 界面的HRTEM 图像:(a)GO/AlSi10Mg,(b)GO/Al[60-61]

Fig.5 HRTEM images of the Al4C3-Al interface in as-built graphene reinforced aluminum matrix composite:(a)GO/AlSi10Mg,(b)GO/Al[60-61]

图6 在500~1 500 nm 波长范围内的激光吸收率随波长的变化:(a)GO/AlSi10Mg,(b)GO/Al[60-61]

Fig.6 Laser absorptivity as a function of wavelength in the range of 500~1 500 nm:(a)GO/AlSi10Mg,(b)GO/Al[60-61]

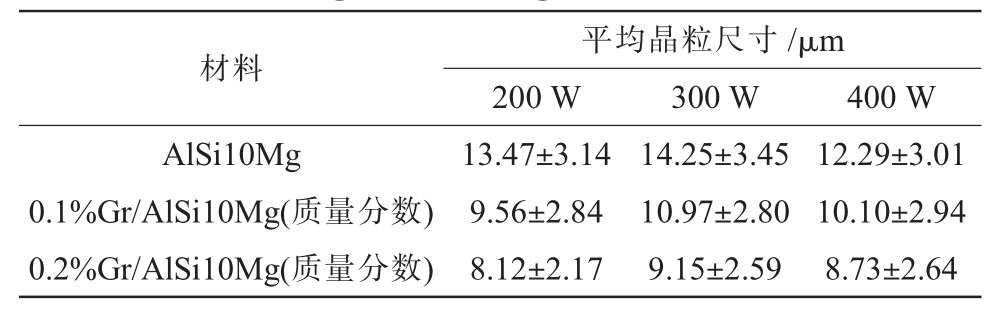

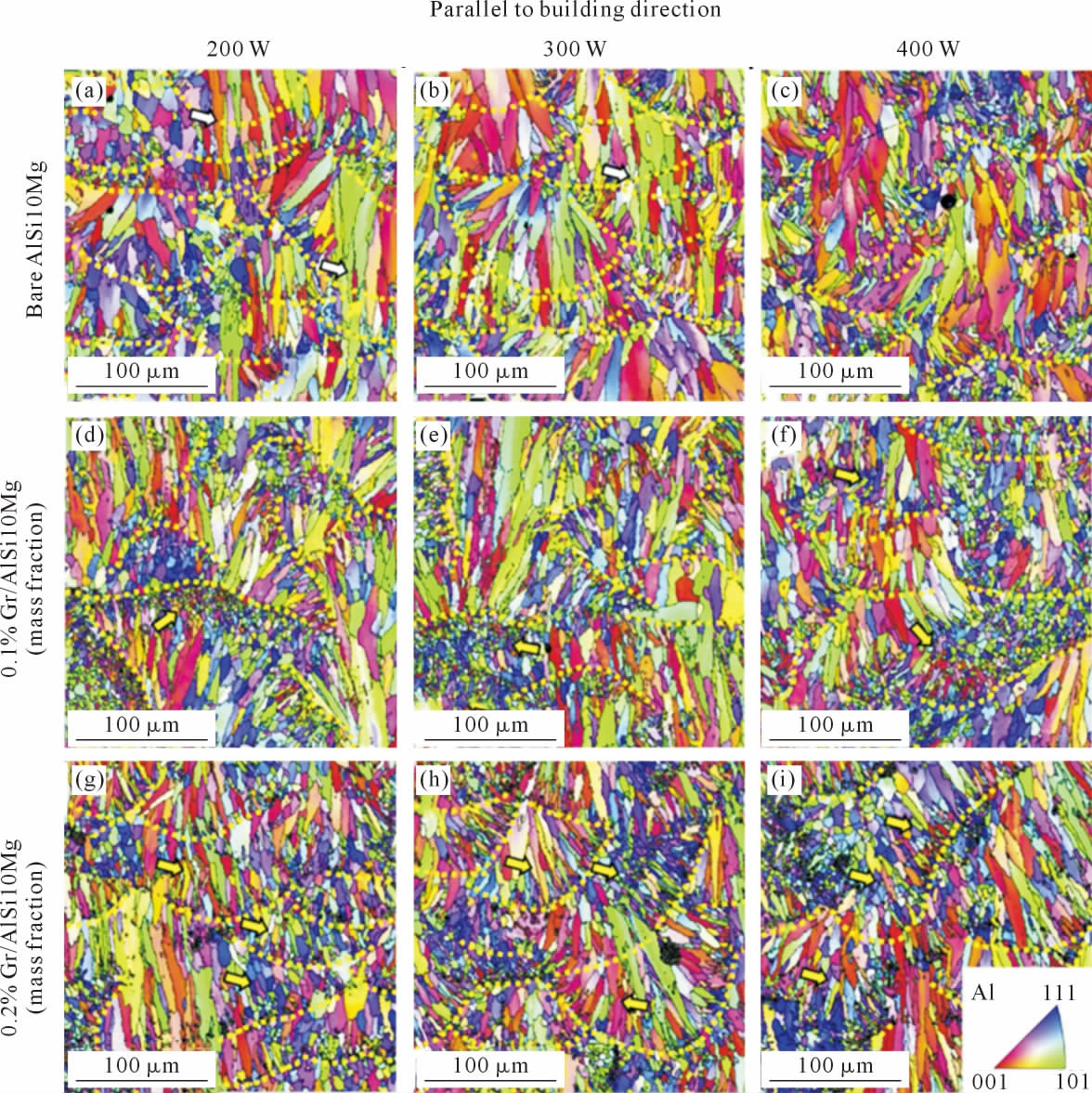

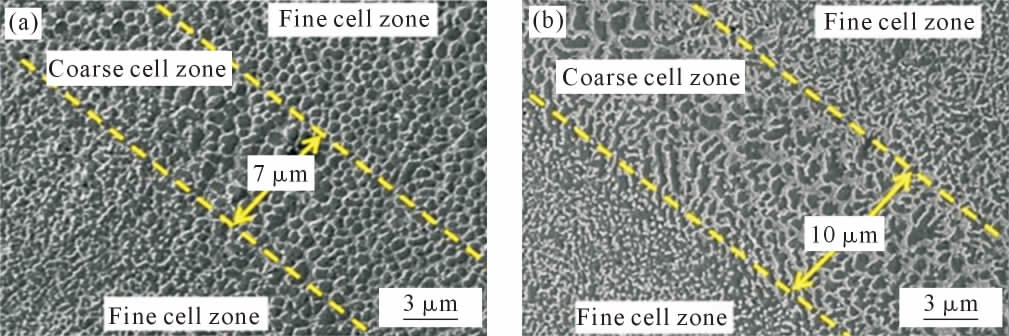

在铝合金打印态样品晶粒形态和尺寸的改变方面, 印度博帕尔先进材料与工艺研究所Tiwari 等[62]采用球磨法制备出石墨烯(Gr)/AlSi10Mg 粉末,通过激光粉末床熔化技术打印样品。 图7 的EBSD 结果表明, 沿着打印方向, 随着石墨烯含量增加,Gr/Al Si10Mg 的组织出现了更多的细小等轴晶,平均晶粒尺寸减小(表2)。 中北大学Zhao 等[63]采用有机铝化学还原和球磨法制备出1%Al(质量分数)包覆石墨烯(Al-coated Gr)/AlSi10Mg 复合粉末, 使用激光粉末床熔化技术打印样品。 图8 表明,在AlSi10Mg 合金中引入Al 包覆石墨烯后,粗晶胞数量减少,形成了更多的细球形晶胞。

表2 合金样品和复合样品沿着打印方向上的平均晶粒尺寸[62]Tab. 2 Average grain size of bare and composite samples along the building direction[62]

?

图7 AlSi10Mg 和Gr/AlSi10Mg 打印态样品在不同打印参数下沿着打印方向的IPF 图[62]

Fig.7 IPF maps of the as-built AlSi10Mg and Gr/AlSi10Mg samples along the building direction at different print parameters[62]

图8 打印态样品显微照片:(a)Al 包覆石墨烯/AlSi10Mg 复合材料的微观结构(横截面),(b)AlSi10Mg 合金的微观结构(横截面)[63]

Fig.8 Micrographs of the as-built samples:(a)Al-coated Gr/AlSi10Mg composite(cross section),(b)AlSi10Mg alloy(cross section)[63]

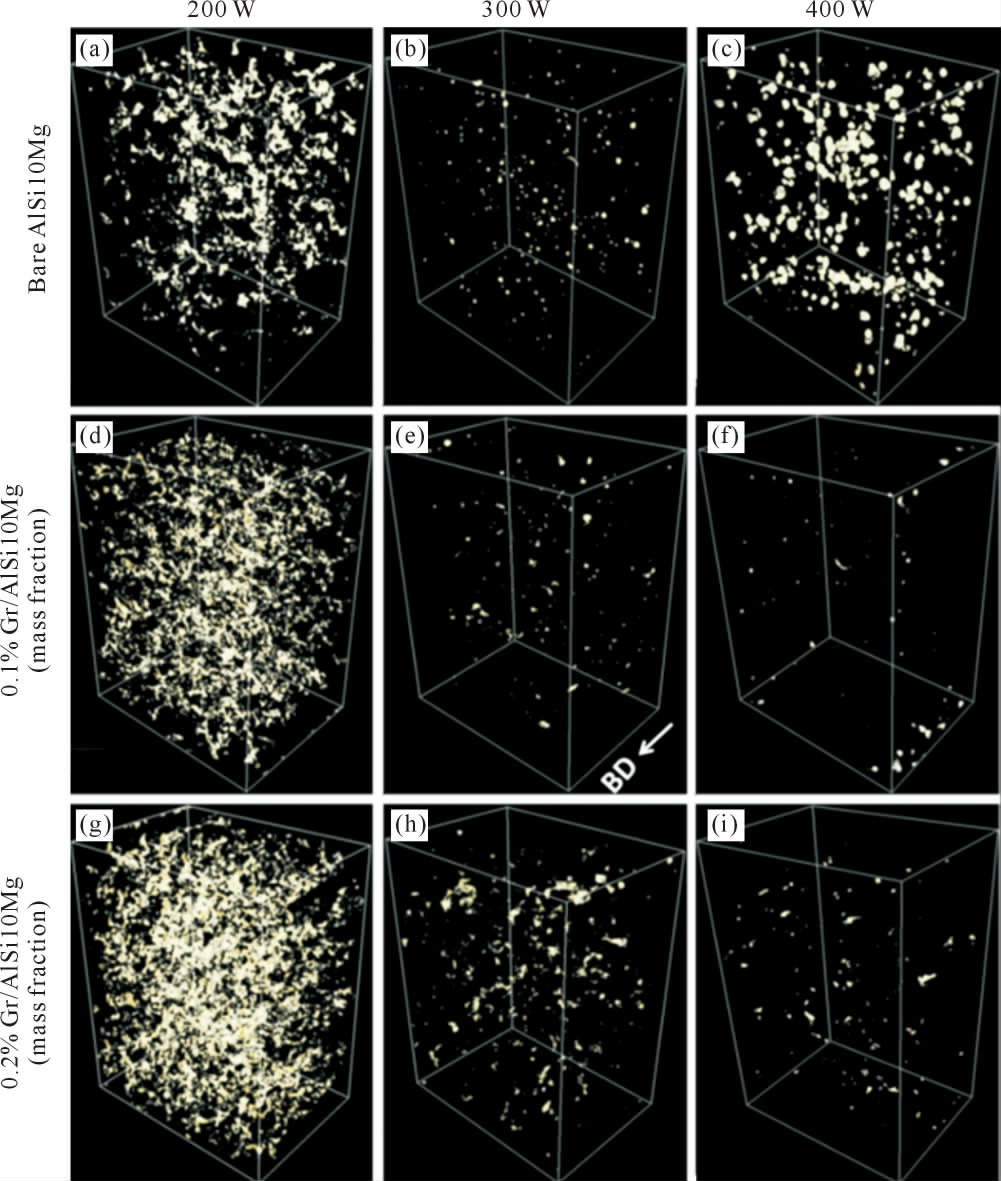

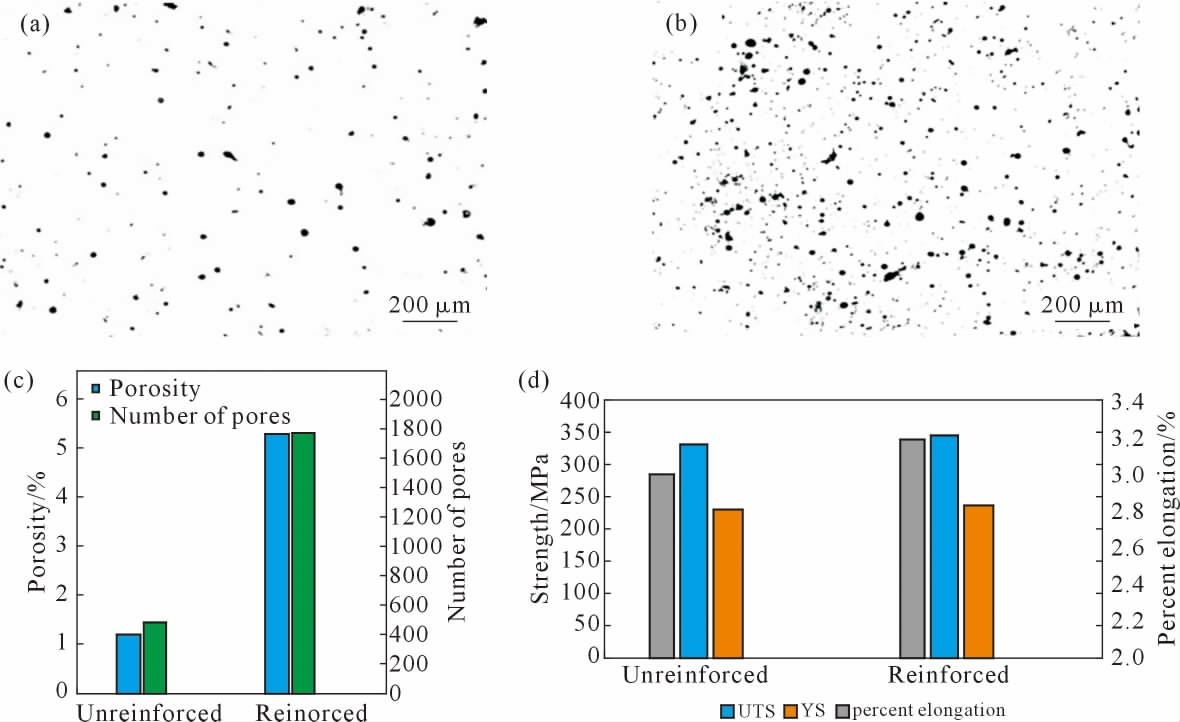

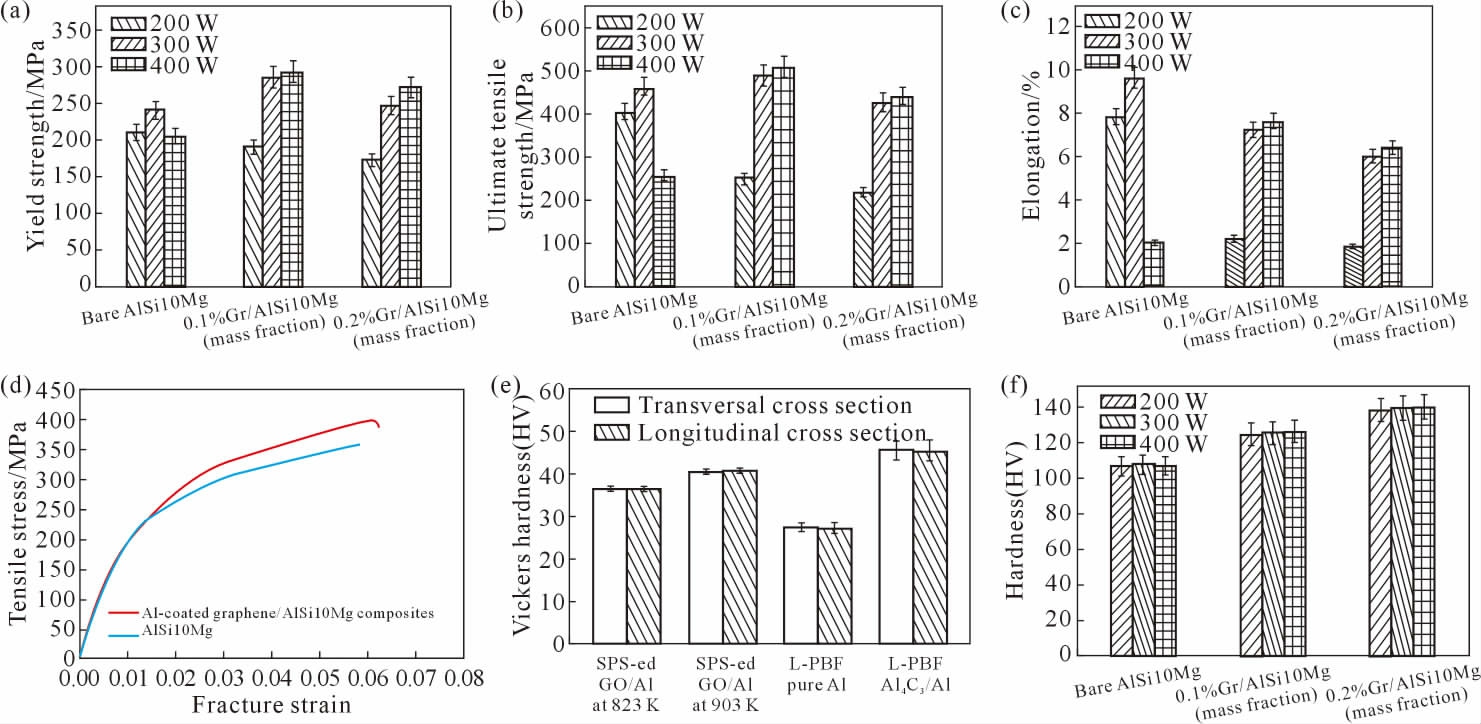

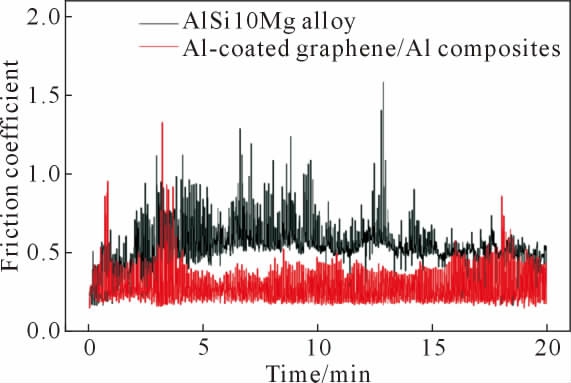

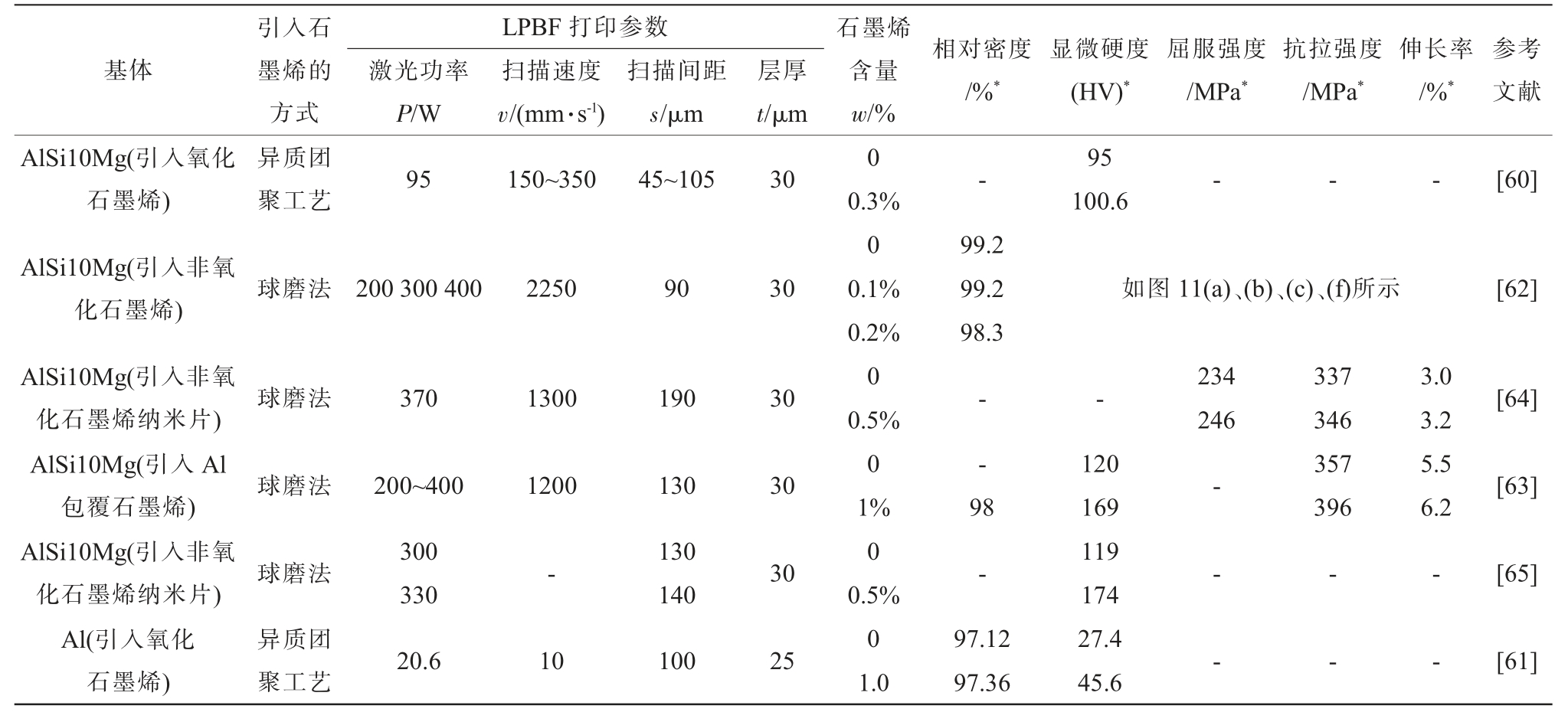

在铝合金打印态样品相对密度、 可打印性以及力学性能的改变方面,Tiwari 等[62]的研究结果如图9所示,当激光功率为300 W 时,AlSi10Mg 的打印态样品孔隙较少;当激光功率增加到400 W 时,质量分数为0.1%和0.2%石墨烯增强样品的孔隙相对较少,复合粉末熔融情况良好。 这说明引入石墨烯后,复合材料的打印参数需要进一步优化, 且相对密度并非随着石墨烯含量增加而增加。 美国辛辛那提大学Wang 等[64]采用球磨法制备出0.5%(质量分数)石墨烯纳米片(GNPs)/AlSi10Mg 粉末,通过激光粉末床熔化技术用相同打印参数打印AlSi10Mg 样品和GNPs/AlSi10Mg 样品。 图10 表明,GNPs/AlSi10Mg打印态样品的相对密度低于AlSi10Mg 打印态样品,但GNPs/AlSi10Mg 的屈服强度、抗拉强度、伸长率高于AlSi10Mg。说明引入0.5%石墨烯(质量分数)对打印态AlSi10Mg 产生了强化效果, 但要提高GNPs/AlSi10Mg 打印态样品的相对密度仍需要进一步优化打印参数。 Tiwari 等[62]、Zhao 等[63]、Zhou等[61]分别对采用激光粉末床熔化技术打印的石墨烯增强铝基复合材料进行相关力学性能实验,结果如图11 所示。 从图11(a~c)及(f)可以看到,0.1%Gr/AlSi10Mg(质量分数)打印态样品的屈服强度和抗拉强度最佳,AlSi10Mg 合金的打印态样品的伸长率最好。 打印态样品的力学性能是由石墨烯的引入和样品的相对密度共同作用,并非引入石墨烯的含量越高,力学性能越好。 但AlSi10Mg 打印态样品的显微硬度随着石墨烯引入量增加而增加。 如图11 (d)所示,Al-coated Gr/AlSi10Mg 打印态样品的抗拉强度为396 MPa,伸长率为6.2%。 Al-coated Gr/AlSi10Mg打印态样品的显微硬度为169 HV。 其抗拉强度、伸长率、显微硬度均高于AlSi10Mg 打印态样品。 如图11(e)所示,可以看到GO/Al 打印态样品(即图中的Al4C3/Al) 的横纵截面的显微硬度要高于纯Al,进一步证明了GO/Al 在打印过程中生成的弥散分布的棒状Al4C3 纳米相具有良好强化效果。 Zhao 等[63]的摩擦实验结果如图12 所示, 打印态Al-coated Gr/AlSi10Mg 平均摩擦系数为0.274, 低于打印态AlSi10Mg 的0.472, 说明打印态Al-coated Gr/Al Si10Mg 的耐磨性优于打印态AlSi10Mg 合金。 Wu等[65]同样用实验证明了打印态GNPs/AlSi10Mg 复合材料的耐磨性更好。 打印态AlSi10Mg 的显微硬度为119 HV,GNPs/AlSi10Mg 的显微硬度为174 HV。 即显微硬度高的铝基复合材料具有良好的耐磨性[66]。

图9 在不同激光功率下制备的合金样品和复合样品中孔隙的体积分布[62]

Fig.9 Volumetric distribution of pores in alloy and composite samples prepared at various laser powers[62]

图10 打印态样品的孔隙分析和拉伸性能:(a)打印态AlSi10Mg 中孔隙的显微照片,(b)打印态GNPs/AlSi10Mg 中孔隙的显微照片,(c)孔隙率比较,(d)拉伸性能[64]

Fig.10 Pore analysis and tensile performance of the as-built samples:(a)micrographs of pores in AlSi10Mg,(b)micrographs of pores in GNPs/AlSi10Mg,(c)porosity comparison,(d)tensile performance[64]

图11 打印态样品的相关力学性能实验结果:(a~c)AlSi10Mg 和Gr/AlSi10Mg 的屈服强度,抗拉强度和伸长率,(d)AlSi10Mg和Al 包覆石墨烯/AlSi10Mg 的工程应力-应变曲线,(e)Al、Al4C3/Al 的横纵截面显微硬度,(f)AlSi10Mg 和Gr/AlSi10Mg 的显微硬度[61-63]

Fig.11 Experimental results of mechanical properties related to the as-built samples:(a~c)yield strength,tensile strength and elongation of AlSi10Mg and Gr/AlSi10Mg,(d)engineering stress-strain curves of AlSi10Mg and Al-coated Gr/AlSi10Mg,(e)microhardness of Al and Al4C3/Al composite in the transversal and longitudinal cross sections,respectively,(f)microhardness of AlSi10Mg and Gr/AlSi10Mg[61-63]

图12 摩擦系数与时间的曲线[63]

Fig.12 The curves of the friction coefficient and time[63]

综上所述, 学者们对石墨烯增强铝基复合材料的众多研究成果表明: ①引入石墨烯能够提高铝及铝合金的激光吸收率,提升可打印性;②引入石墨烯能够细化铝合金打印态样品的晶粒尺寸, 提高显微硬度和耐磨性。但目前的研究结果仍有不完善之处:铝基复合材料的相对密度和拉伸力学性能并非随着引入石墨烯含量的增加而提升, 需要综合考虑打印参数的影响。 为了使得石墨烯增强铝基复合材料的打印态样品能达到较优强化效果, 对于不同牌号的铝合金,引入石墨烯的含量、打印参数和最终打印态样品的相对密度、力学性能之间的相互作用关系,仍有待进一步研究。

表3为总结的文献中一些石墨烯增强铝基复合材料的相关数据。

表3 石墨烯增强铝基复合材料数据表(“*”表示最大值)

Tab.3 Data sheet of graphene reinforced aluminum matrix composites (“*” is maximum)

?

3 TiC 增强

TiC 具有高硬度、高弹性模量、良好润湿性、良好激光吸收率等优点[67-68]。TiC 纳米颗粒引入铝及铝合金的方式以外加法(球磨法、超声搅拌法等)为主。起初,超声辅助搅拌铸造、喷雾沉积、粉末冶金等是用于制备TiC 纳米颗粒增强铝基复合材料的主要工艺[69-74]。近年来由于增材制造技术的不断应用和推广,TiC 纳米颗粒增强铝基复合材料的生产工艺得以逐步向以激光粉末床熔化为代表的增材制造技术过渡和发展。 引入TiC 纳米颗粒能够改变铝合金打印态样品的晶粒形态、晶粒尺寸、相对密度、可打印性和力学性能。

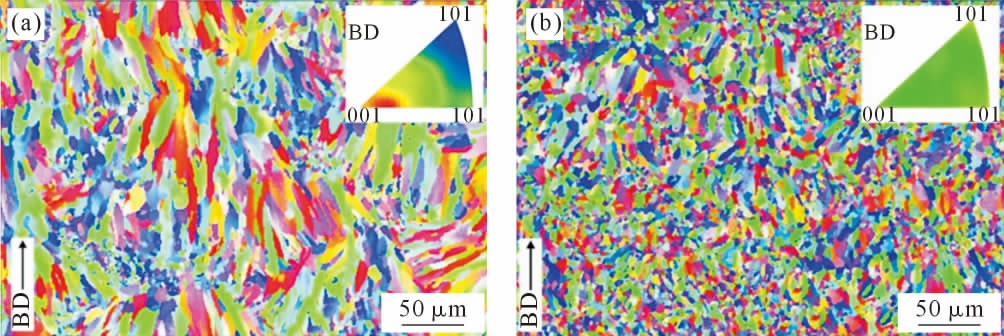

在铝合金打印态样品晶粒形态和尺寸的改变方面,南昌航空大学Fan 等[75]采用球磨法使得TiC 纳米颗粒均匀分布在AA2024 铝合金粉末表面, 制成了TiC/AA2024 复合粉末, 并采用激光粉末床熔化技术打印样品。 经过EBSD 分析表征,发现随着引入TiC 纳米颗粒含量的增加, 能够细化打印态AA2024 铝合金的晶粒尺寸, 促进柱状晶向等轴晶的转变。 山东大学贾增庆等[76]使用真空感应气雾化方法制备出了AlSi10Mg 合金+2024 铝合金+1.5%TiC(质量分数)的复合粉末,命名为AlSi10Mg-2024(TiC),并采用激光粉末床熔化技术打印样品。 图13为打印态样品沿着打印方向的EBSD 结果,从图13(a~b) 对比可以看出,TiC 纳米颗粒起到了细化晶粒和促进柱状晶向等轴晶转变的作用, 并有效改善了打印态样品的各向异性。 美国辛辛那提大学Wang等[77]将AlSi10Mg 粉末和TiC 纳米颗粒通过湿球磨和超声搅拌的方式进行混合, 得到3.0%TiC/Al Si10Mg(质量分数)复合粉末,并采用激光粉末床熔化技术打印样品。 研究表明,引入TiC 纳米颗粒会细化AlSi10Mg 打印态样品的晶粒尺寸, 促进柱状晶向等轴晶转变。

图13 沿打印方向IPF 图:(a)AlSi10Mg 合金,(b)AlSi10Mg-2024(TiC)[76]

Fig.13 IPF maps along the building direction:(a)AlSi10Mg alloy,(b)AlSi10Mg-2024(TiC)[76]

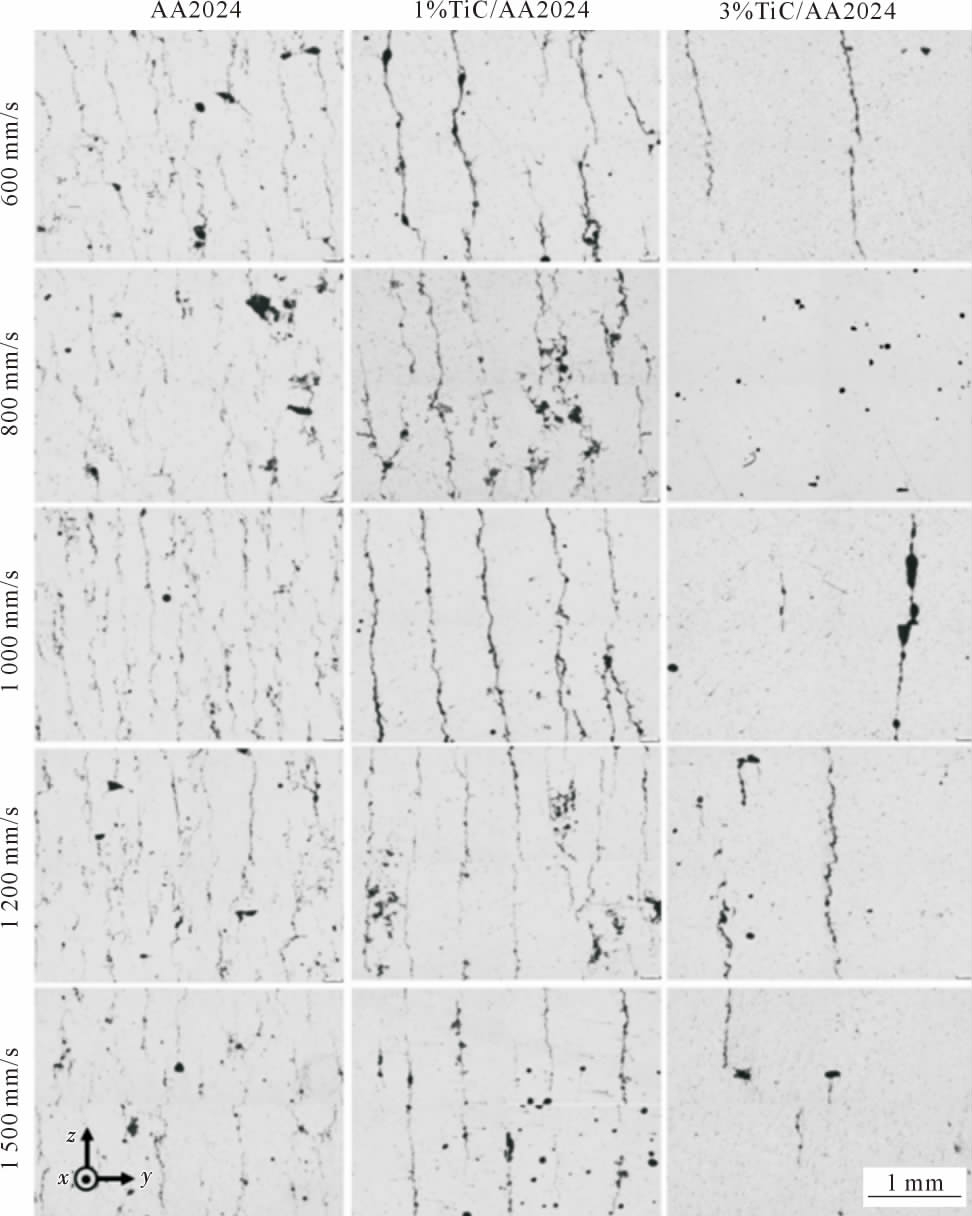

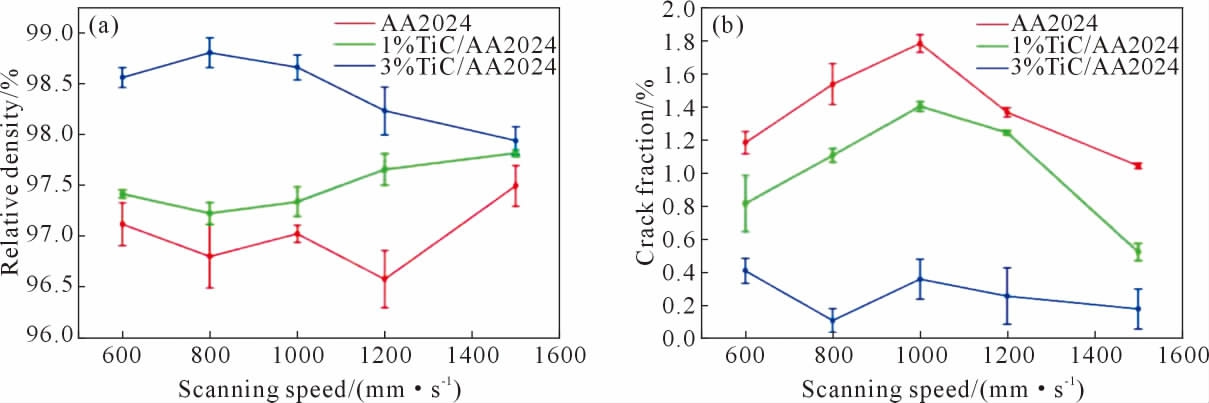

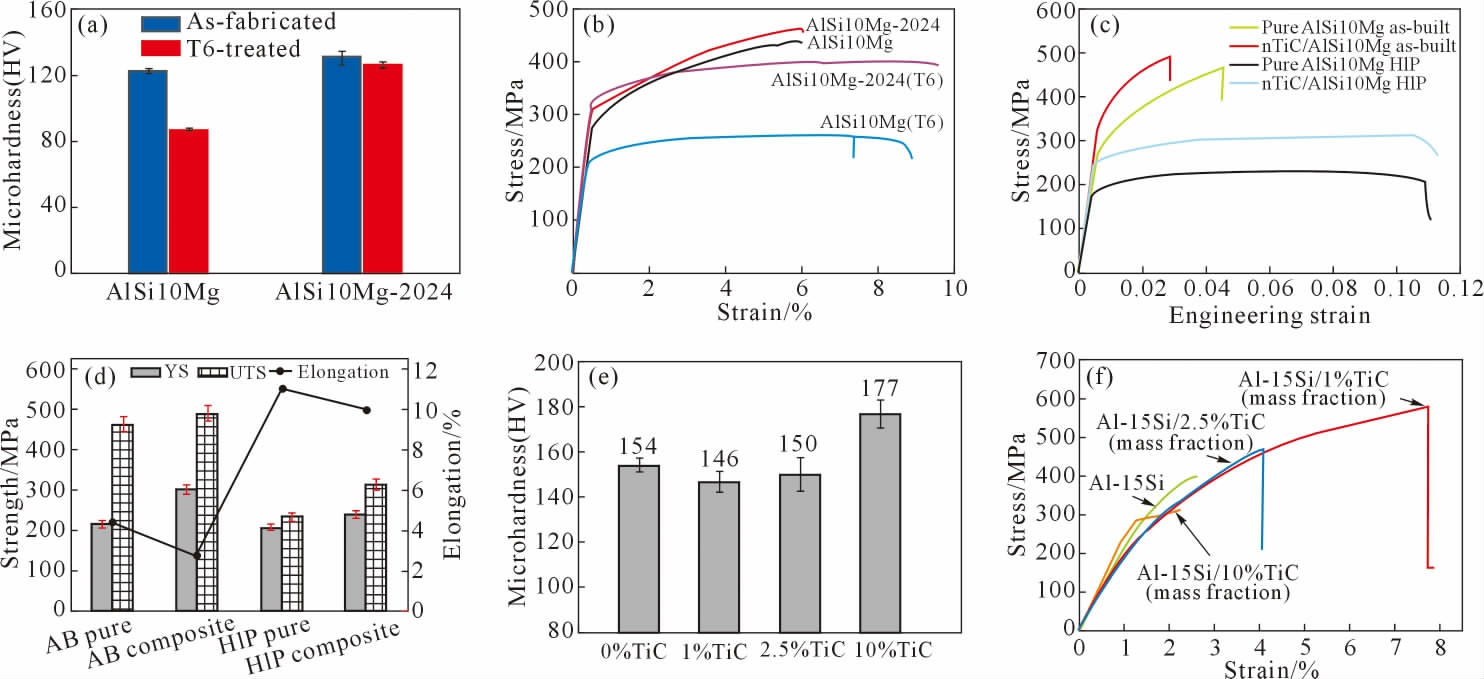

在铝合金打印态样品相对密度、可打印性的改变方面,Fan 等[75]对打印态样品的相对密度和裂纹分析如图14~15 所示, 在激光扫描速度为600~1 500 mm/s的工艺窗口下,未引入TiC 纳米颗粒的AA2024 铝合金打印态样品的热裂纹面积分数较大。 随着引入的TiC 纳米颗粒含量增加, 热裂纹面积分数减小,样品相对密度逐渐增加,说明引入TiC 纳米颗粒提升了AA2024 铝合金的可打印性。 在铝合金打印态样品力学性能的改变方面,贾增庆等[76]、Wang 等[77]分别对采用激光粉末床熔化技术打印的TiC 增强铝基复合材料进行相关力学性能实验, 实验结果如图16 所示。 贾增庆等[76]的实验结果(图16(a~b))表明,AlSi10Mg-2024(TiC)打印态样品的显微硬度、屈服强度和抗拉强度相较于AlSi10Mg 合金均有所提高。 Wang 等[77]的研究(图16(c~d))发现,3.0%TiC/AlSi10Mg(质量分数)打印态样品的屈服强度和抗拉强度均高于AlSi10Mg 打印态样品, 但是Al-Si10Mg 打印态样品的伸长率更高。 中国地质大学(武汉)Zhou 等[78]采用球磨法分别制备出了质量分数为1%、2.5%、10%TiC/Al-15Si 复合粉末, 通过激光粉末床熔化技术打印样品, 并进行了相关力学性能测试。 从图16(e~f)可以看出,随着TiC 含量增加,TiC/Al-15Si 的显微硬度先减小后增大;抗拉强度和伸长率先增大后减小。

图14 不同激光功率打印态合金和复合样品OM 图[75]

Fig.14 OM images of the as-built alloy and composite samples at various laser powers[75]

图15 打印态样品相对密度和裂纹分析:(a)AA2024 铝合金和复合样品的相对密度和扫描速度的关系,(b)AA2024 铝合金和复合样品裂纹面积分数和扫描速度的关系[75]

Fig.15 Relative density and crack analysis of the as-built samples:(a)the relative density of AA2024 Al alloy and composite at different laser scanning speeds,(b)the area fraction of cracks in AA2024 Al alloy and composite at different laser scanning speeds[75]

图16 打印态样品的相关力学性能实验结果:(a~b)打印态和T6 热处理后AlSi10Mg 和AlSi10Mg-2024(TiC)的显微硬度及工程应力-应变曲线,(c~d)AlSi10Mg 和TiC/AlSi10Mg 的工程应力-应变曲线及屈服强度、抗拉强度、伸长率的比较,(e~f)Al-15Si 和TiC/Al-15Si 的显微硬度及工程应力-应变曲线[76-78]

Fig.16 Experimental results of mechanical properties related to the as-built samples:(a~b)microhardness and engineering stress-strain curves of AlSi10Mg and AlSi10Mg-2024(TiC)both in as-built condition and after T6 heat treatment,(c~d)engineering stress-strain curves and comparison of yield strength,tensile strength,elongation of AlSi10Mg and TiC/AlSi10Mg,(e~f)microhardness and engineering stress-strain curves of Al-15Si and TiC/Al-15Si[76-78]

综上所述,学者们对TiC 纳米颗粒增强铝基复合材料的众多研究成果表明:①引入TiC 纳米颗粒能够细化铝合金打印态样品的晶粒尺寸, 增加细等轴晶比例;②引入TiC 纳米颗粒能够改善铝合金的热裂纹缺陷, 提高可打印性。 但目前的研究仍然有待完善:引入TiC 纳米颗粒并不一定能够提升铝合金打印态样品的显微硬度和拉伸力学性能,TiC 纳米颗粒增强铝基复合材料的力学性能是一个由TiC纳米颗粒含量、激光粉末床熔化打印参数、铝基复合材料的组织、 打印态样品相对密度等因素共同作用和影响的结果, 之间的复杂关系仍然需要进行进一步研究。

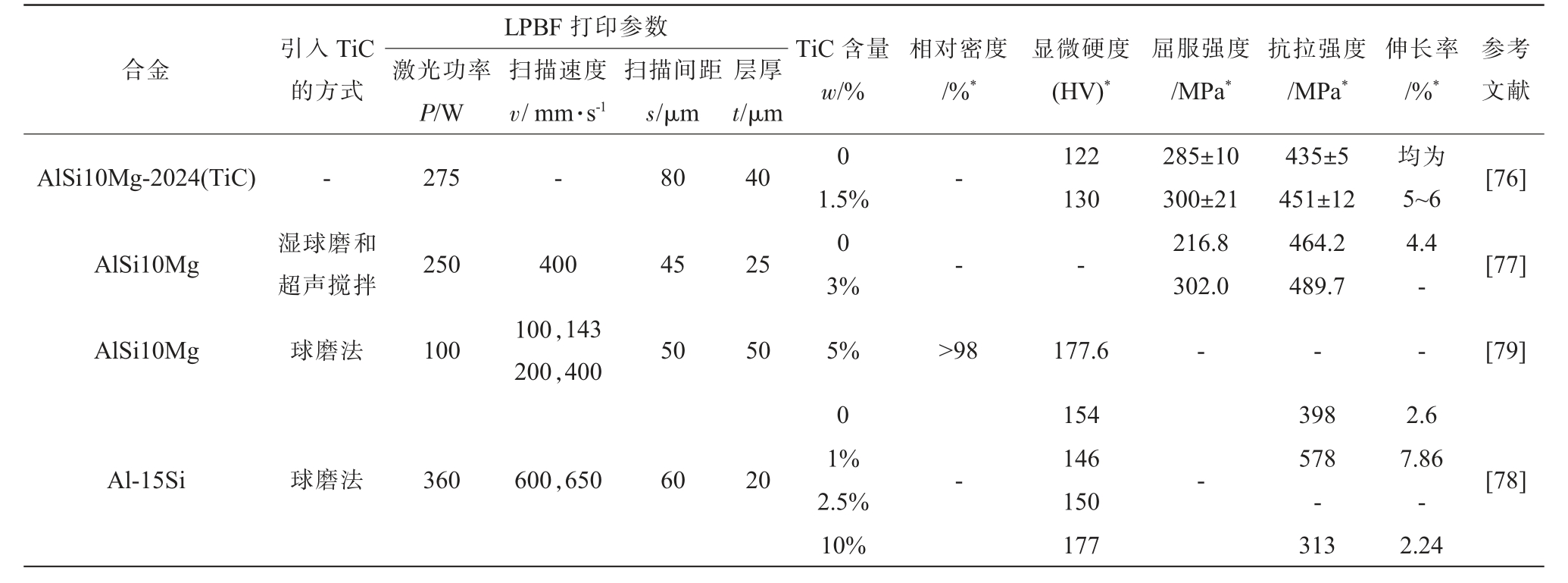

表4为总结的文献中一些TiC 增强铝基复合材料的相关数据。

表4 TiC 增强铝基复合材料数据表(“*”表示最大值)

Tab. 4 Data sheet of TiC reinforced aluminum matrix composites (“*” is maximum)

?

4 不同纳米增强体对打印态铝合金力学性能影响的对比

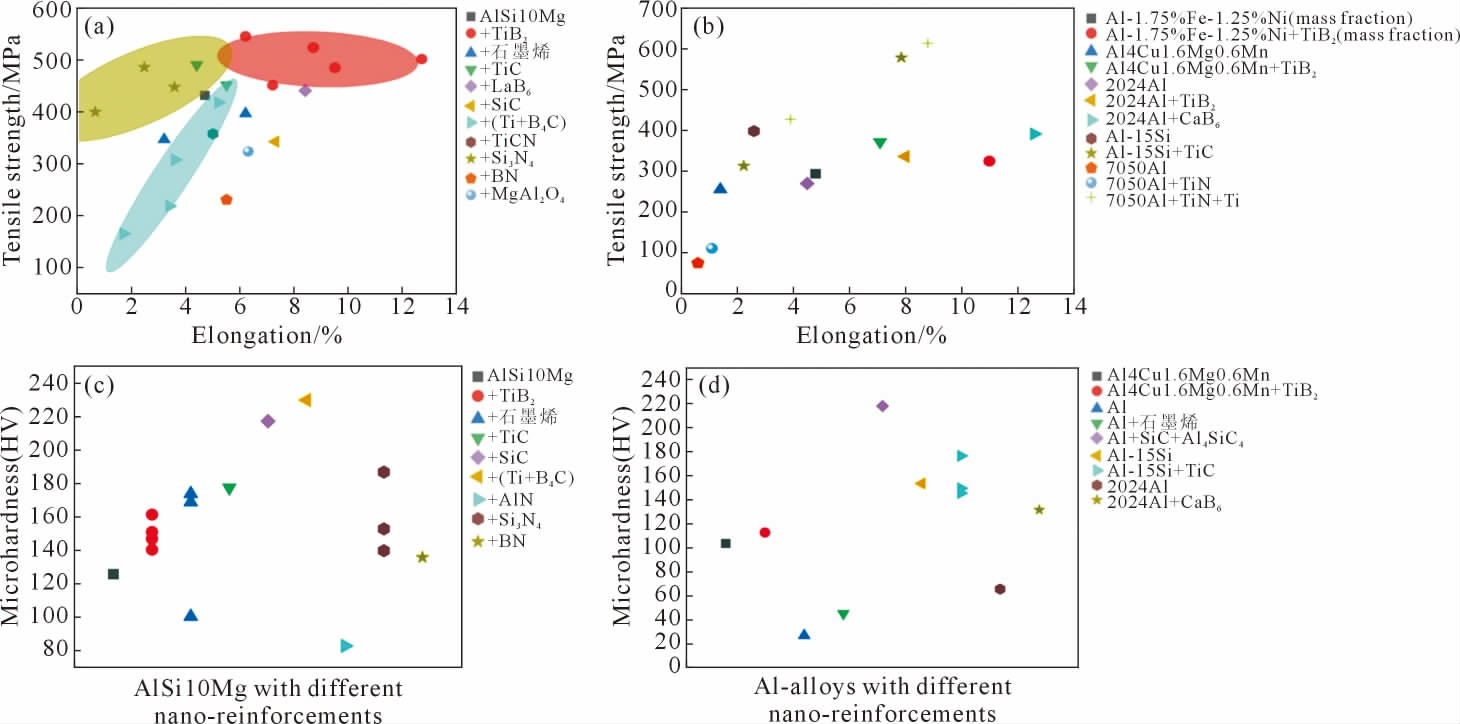

近年来, 关于向铝合金中引入的纳米增强体层出不穷,主要分为五大类:硼化物、碳单质、碳化物、氮化物、金属氧化物。 除了本文提到的TiB2、石墨烯、TiC,还有LaB6[80]、CaB6[81]、金刚石[82]、SiC[83-85]、B4C[86]、Al4SiC4[87]、AlN [88-89]、TiN [90]、TiCN [91]、Si3N4[92]、BN [93]、Fe3O4[28]、MgAl2O4[94]等。 这些纳米增强体对打印态铝合金力学性能的改善可归结为以下两大机理: ①引入的纳米增强体能够作为异质形核位点, 促进激光粉末床熔化打印凝固过程中的晶粒形核, 形成更多细小等轴晶,细化晶粒尺寸,产生细晶强化;②引入的纳米增强体会形成弥散分布的第二相粒子, 产生第二相强化。 为了直观反映出现有主流纳米增强体对打印态铝合金力学性能改变的分布情况, 结合文献中的数据,作出了图17。

图17 不同纳米增强体对打印态铝合金力学性能改变的对比:(a~b)AlSi10Mg 及其他铝合金抗拉强度和伸长率,(c~d)AlSi10Mg及其他铝合金显微硬度[45-46,48,51,60-61,63-65,76-81,84,86-87,89-94]

Fig.17 Comparison of different nano-reinforcements on the change in the mechanical properties of the as-built aluminum alloys:(a~b)tensile strength and elongation of AlSi10Mg and other Al-alloys,(c~d)microhardness of AlSi10Mg and other Al-alloys[45-46,48,51,60-61,63-65,76-81,84,86-87,89-94]

从图17(a)可以看出,对于打印态AlSi10Mg,引入TiB2 能够使其抗拉强度和伸长率都得到提高;引入LaB6 对其伸长率提高较大,但抗拉强度变化不明显; 引入TiC 和Si3N4 对其抗拉强度有一定提高作用,但伸长率出现了下降的现象;而其他纳米增强体效果不理想, 甚至出现了抗拉强度降低的现象。 因此,TiB2 纳米颗粒的引入对于打印态AlSi10Mg 来说效果非常良好, 对强塑性均有提升的作用。 从图17(b)可以看出,对于其他牌号的打印态铝合金,引入相应的纳米增强体都实现了抗拉强度和伸长率的一定提高。如图17(c)所示,除了AlN,其余纳米增强体都能够提高打印态AlSi10Mg 的显微硬度。 如图17(d)所示,对于其他牌号的打印态铝合金,引入相应的纳米增强体对显微硬度都有所提高。

综上所述,以TiB2 为代表的纳米增强体对打印态铝合金的强化效果良好,能够起到强度、塑性均有提升的效果。 但不同牌号铝合金强化效果最佳的纳米增强体种类及引入的含量仍需要再进一步研究。

5 结论

(1)在铝合金中引入TiB2、石墨烯、TiC 纳米增强体所制备出的铝基复合材料, 能够提高铝合金的激光吸收率; 促进组织中的粗大柱状晶向细等轴晶转变,细化晶粒尺寸;改善铝合金在激光粉末床熔化加工过程中的热裂纹缺陷,提升可打印性。

(2)在铝合金中引入TiB2、石墨烯、TiC 纳米增强体能够调整材料的力学性能, 但铝合金力学性能的改变并非和引入纳米增强体的含量呈简单的正相关关系。同样,铝基复合材料的相对密度也并不一定随着引入纳米增强体含量的增加而增加。 铝基复合材料的力学性能是一个由纳米增强体含量、 激光粉末床熔化打印参数、铝基复合材料的组织、打印态样品相对密度等因素共同作用的复杂结果。

(3)原位自生引入TiB2 纳米颗粒的方式能够获得均匀的颗粒分布, 且在原材料制备阶段即引入强化颗粒相,减少了球磨混合的工序,适合批量化增材制造应用。

6 前景展望

(1)针对于不同牌号的铝合金和种类繁多的纳米增强体, 每种铝合金对应引入何种纳米增强体能够起到相对较优的缺陷改善效果和可打印性、 力学性能等性能的提升,是有待进一步研究的问题。

(2)在航空航天、军工、交通运输等领域所用到的铝基复合材料关键部件需要重点关注其力学性能的优劣和相对密度的高低问题。 打印态铝基复合材料的力学性能和相对密度并不一定随着纳米增强体含量的增加而提升, 还需要综合考虑激光粉末床熔化的最优打印工艺参数的问题。因此,能否建立不同种类铝基复合材料的力学性能、 相对密度和激光粉末床熔化打印工艺参数及引入纳米增强体含量的定量关系极为关键,具有很大研究前景,若能针对具体情况给出数值模拟计算模型作为铝基复合材料力学性能的预测, 则能够提高设计实验研究方案和制定加工参数的效率。

(3)为了阐明纳米增强体在激光粉末床熔化打印过程中发生的现象和变化, 数值模拟和实验方法需要进一步发展。因此,通过建立相关物理模型对纳米增强体在熔池中的行为进行数值模拟, 并采用X射线同步辐射对打印过程进行原位观测, 可以帮助深入理解内在机理并更好地进行打印工艺参数的优化。

(4)热等静压(hot isostatic pressing,HIP)能够起到焊合打印态样品裂纹的作用, 但其高温环境会造成铝基复合材料的晶粒尺寸有所增加。因此,能否采用HIP 来帮助改善热裂纹缺陷,并对力学性能产生较小的影响是有待进一步研究的问题。

(5)采用激光粉末床熔化技术制备的铝基复合材料会在未来释放更大潜力,推动航空航天、军工、交通运输等行业进一步发展。

[1] 房豪杰,曲华,杨黎晖,等.9C 系列粉末冶金高耐蚀铝合金腐蚀行为研究[J].中国腐蚀与防护学报,2021,41(6):775-785.FANG H J,QU H,YANG L H,et al.Corrosion behavior of 9C series of powder metallurgy Al-alloy with high corrosion resistance[J].Journal of Chinese Society for Corrosion and Protection,2021,41(6):775-785.

[2] 马晓波,王东新,胡侨丹,等. 元素添加强化铍铝合金研究现状[J].稀有金属,2021,45(8):1010-1017.MA X B,WANG D X,HU Q D,et al.Research status of additive elements to strengthen beryllium aluminum alloy[J].Chinese Journal of Rare Metals,2021,45(8):1010-1017.

[3] SUN T T, WANG H Z, GAO Z Y, et al. The role of in-situ nano-TiB2 particles in improving the printability of noncastable 2024Al alloy[J].MaterialsResearchLetters,2022,10(10):656-665.

[4] SUN T T, CHEN J, WU Y, et al. Achieving excellent strength of the LPBF additively manufactured Al-Cu-Mg composite via in-situ mixing TiB2 and solution treatment [J].Materials Science and Engineering:A,2022,850:143531.

[5] 齐世文,荣鹏,黄丹,等. 激光粉末床熔融增材制造铝合金的室温和高温力学性能研究[J].中国激光,2022,49(8):7-17.QI S W,RONG P,HUANG D,et al.Room-and high-temperature mechanical properties of aluminum alloys fabricated using laser powder bed fusion additive manufacturing[J].Chinese Journal of Lasers,2022,49(8):7-17.

[6] 胡娟,高银涛,冒浴沂,等. 激光粉末床熔融金属制件孔隙缺陷研究现状[J].粉末冶金工业,2021,31(6):87-93.HU J, GAO Y T, MAO Y Y, et al. Research progress of pore defects for metal parts manufactured by laser powder bed fusion[J].Powder Metallurgy Industry,2021,31(6):87-93.

[7] XIAO Y K, BIAN Z Y, WU Y, et al. Simultaneously minimizing residual stress and enhancing strength of selective laser melted nano-TiB2 decorated Al alloy via post-uphill quenching and ageing[J].Materials Characterization,2021,178:111242.

[8] DING H,XIAO Y K,BIAN Z Y,et al.Design,microstructure and thermal stability of a novel heat-resistant Al-Fe-Ni alloy manufactured by selective laser melting[J]. Journal of Alloys and Compounds,2021,885:160949.

[9] 卢秉恒,李涤尘. 增材制造(3D 打印)技术发展[J]. 机械制造与自动化,2013,42(4):1-4.LU B H,LI D C.Development of the additive manufacturing (3D printing)technology[J].Machine Building & Automation, 2013,42(4):1-4.

[10] 王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题[J].航空学报,2014,35(10):2690-2698.WANG H M.Materials'fundamental issues of laser additive manufacturing for high-performance large metallic components[J].Acta Aeronautica et Astronautica Sinica,2014,35(10):2690-2698.

[11] LOUVIS E,FOX P,SUTCLIFFE C J.Selective laser melting of aluminium components[J].Journal of Materials Processing Technology,2011,211(2):275-284.

[12] REDDY B V, DEEVI S C. Thermophysical properties of FeAl(Fe-40 at.%Al)[J].Intermetallics,2000,8(12):1369-1376.

[13] LI S,CAI B,DUAN R X,et al.Synchrotron characterisation of ultra-fine grain TiB2/Al-Cu composite fabricated by laser powder bed fusion[J].Acta Metallurgica Sinica(English Letters),2021,35(1):78-92.

[14] WANG J H, LIU T, LUO L S, et al. Selective laser melting of high-strength TiB2/AlMgScZr composites: Microstructure, tensile deformation behavior, and mechanical properties[J]. Journal of Materials Research and Technology,2022,16:786-800.

[15] PARSONS E M,SHAIK S Z.Additive manufacturing of aluminum metal matrix composites: Mechanical alloying of composite powders and single track consolidation with laser powder bed fusion[J].Additive Manufacturing,2022,50:102450.

[16] TREVISAN F,CALIGNANO F,LORUSSO M,et al.On the selective lasermelting(SLM)of theAlSi10Mgalloy:Process,microstructure,and mechanical properties[J].Materials,2017,10:1-23.

[17] TANG M, PISTORIUS P C. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting[J].International Journal of Fatigue,2017,94:192-201.

[18] ABOULKHAIR N T,EVERITT N M,ASHCROFT I,et al.Reducing porosity in AlSi10Mg parts processed by selective laser melting[J].Additive Manufacturing,2014,1:77-86.

[19] GARG P, JAMWAL A, KUMAR D, et al. Advance research progresses in aluminium matrix composites: Manufacturing & applications[J].Journal of Materials Research and Technology,2019,8(5):4924-4939.

[20] MIRACLE D B.Metal matrix composites-from science to technological significance[J].Composites Science and Technology,2005,65(15-16):2526-2540.

[21] ESSIEN U A,VAUDREUIL S.In-situ metal matrix composites development for additive manufacturing:A perspective[J].Journal of Achievements in Materials and Manufacturing Engineering, 2022,111(2):78-85.

[22] YU W H, SING S L, CHUA C K, et al. Particle-reinforced metal matrix nanocomposites fabricated by selective laser melting: A state of the art review[J].Progress in Materials Science,2019,104:330-379.

[23] WANG P,ECKERT J,PRASHANTH K G,et al.A review of particulate-reinforced aluminum matrix composites fabricated by selective laser melting[J].Transactions of Nonferrous Metals Society of China,2020,30(8):2001-2034.

[24] FENG Z,WANG X M,TAN H,et al.Effect of heat treatment patterns on porosity,microstructure,and mechanical properties of selective laser melted TiB2/Al-Si-Mg composite[J]. Materials Science and Engineering:A,2022,855:143932.

[25] BOILLAT R,ISANAKA S P,LIOU F.The effect of nanostructures in aluminum alloys processed using additive manufacturing on microstructural evolution and mechanical performance behavior[J].Crystals,2021,11(5):524.

[26] SHI J, WANG Y C. Development of metal matrix composites by laser-assisted additive manufacturing technologies: A review[J].Journal of Materials Science,2020,55(23):9883-9917.

[27] SADEGHI B, CAVALIERE P, PRUNCU C I, et al. Architectural design of advanced aluminum matrix composites: A review of recent developments[J]. Critical Reviews in Solid State and Materials Sciences,2022:1-71.

[28] ANOOP J, SUYAMBURAJAN V A, BABU P S, et al. Analysis and experimental investigation of A356 aluminium alloy hybrid composites reinforced with Gr-Fe3O4-B4C nanoparticles synthesised by selective laser melting (SLM)[J].Journal of Nanomaterials,2022,2022:7510499.

[29] KUSOGLU I M,GÖKCE B,BARCIKOWSKI S.Use of(nano-)additives in laser powder bed fusion of Al powder feedstocks: Research directions within the last decade[J].Procedia CIRP,2020,94:11-16.

[30] TANG S Y,UMMETHALA R,SURYANARAYANA C,et al.Additive manufacturing of aluminum-based metal matrix composites-a review[J].Advanced Engineering Materials,2021,23(7):2100053.

[31] WANG Z,QU R T,SCUDINO S,et al.Hybrid nanostructured aluminum alloy with super-high strength[J].NPGAsiaMaterials,2015,7:e229.

[32] AMIRKHANLOU S, JI S X. A review on high stiffness aluminum-based composites and bimetallics[J]. Critical Reviews in Solid State and Materials Sciences,2019,45(1):1-21.

[33] KARABULUT Y, ÜNAL R. Additive manufacturing of ceramic particle-reinforced aluminum-based metal matrix composites: A review[J].Journal of Materials Science, 2022,57:19212-19242.

[34] FEREIDUNI E, GHASEMI A, ELBESTAWI M. Selective laser melting of aluminum and titanium matrix composites: Recent progress and potential applications in the aerospace industry[J].Aerospace,2020,7(6):77.

[35] MINASYAN T,HUSSAINOVA I.Laser powder-bed fusion of ceramic particulate reinforced aluminum alloys:A review[J].Materials,2022,15(7):2467.

[36] CHEN B,XI X,TAN C W,et al.Recent progress in laser additive manufacturing of aluminum matrix composites[J]. Current Opinion in Chemical Engineering,2020,28:28-35.

[37] XI L X,GU D D,GUO S,et al.Grain refinement in laser manufactured Al-based composites with TiB2 ceramic [J].Journal of Materials Research and Technology,2020,9(3):2611-2622.

[38] PRAMOD S L,BAKSHI S R,MURTY B S.Aluminum-based cast in situ composites:A review[J].Journal of Materials Engineering and Performance,2015,24(6):2185-2207.

[39] SINGH N,BELOKAR R M,WALIA R S.A critical review on advanced reinforcements and base materials on hybrid metal matrix composites[J].Silicon,2020,14(2):335-358.

[40] ESAKKIRAJ E S, SURESH S, MOORTHI N S V, et al. Study of mechanical behaviour of stir cast aluminium based composite reinforced with mechanically ball milled TiB2 nano particles [J]. Advanced Materials Research,2014,984-985:410-415.

[41] LIU X,LIU Y,HUANG D,et al.Tailoring in-situ TiB2 particulates in aluminum matrix composites[J]. Materials Science and Engineering:A,2017,705:55-61.

[42] SETHI D,KUMAR S,CHOUDHURY S,et al.Synthesis and characterization of AA7075/TiB2 aluminum matrix composite formed through stir casting method[J].Materials Today:Proceedings,2020,26:1908-1913.

[43] 甘贵生,杨滨.TiB2/7075 铝基复合材料流变挤压成形工艺[J]. 中国有色金属学报,2014,24(5):1133-1140.GAN G S, YANG B. Rheo-casting forming process of TiB2/7075 aluminium matrix composites[J].The Chinese Journal of Nonferrous Metals,2014,24(5):1133-1140.

[44] GUO L P,WANG H Z,WEI Q L,et al.A comprehensive model to quantify the effects of additional nano-particles on the printability in laser powder bed fusion of aluminum alloy and composite[J].Additive Manufacturing,2022,58:103011.

[45] DING H,XIAO Y K,BIAN Z Y,et al.Effect of in-situ TiB2 particles on microstructure and mechanical properties of Al-Fe-Ni manufactured by selective laser melting [J].Materials Science and Engineering:A,2022,845:143065.

[46] SUN T T, XIAO Y K, LUO G D, et al. Roadmap to improve the printability of a non-castable alloy for additive manufacturing[J].Metallurgical and Materials Transactions A,2022,53:2780-2795.

[47] LI X P, JI G, CHEN Z, et al. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility[J].Acta Materialia,2017,129:183-193.

[48] WANG Q Z,LIN X,KANG N,et al.Effect of laser additive manufacturing on the microstructure and mechanical properties of TiB2 reinforced Al-Cu matrix composite[J].Materials Science and Engineering:A,2022,840:142950.

[49] WANG R Q, XI L X, DING K, et al. Powder preparation during ball milling and laser additive manufacturing of aluminum matrix nanocomposites:Powder properties,processability and mechanical property[J].Advanced Powder Technology,2022,33(8):103687.

[50] XIAO Y K,BIAN Z Y,WU Y,et al.Effect of nano-TiB2 particles on the anisotropy in an AlSi10Mg alloy processed by selective laser melting[J].JournalofAlloysand Compounds,2019,798:644-655.

[51] XIAO Y K, CHEN H, BIAN Z Y, et al. Enhancing strength and ductility of AlSi10Mg fabricated by selective laser melting by TiB2 nanoparticles[J].Journal of Materials Science & Technology,2022,109:254-266.

[52] XIAO Y K,YANG Q,BIAN Z Y,et al.Microstructure,heat treatment and mechanical properties of TiB2/Al-7Si-Cu-Mg alloy fabricated by selective laser melting[J]. Materials Science and Engineering:A,2021,809:140951.

[53] BIFFI C A,BASSANI P,FIOCCHI J,et al.Selective laser melting of AlCu-TiB2 alloy using pulsed wave laser emission mode: Processability,microstructure and mechanical properties[J].Materials&Design,2021,204:109628.

[54] NIETO A,BISHT A,LAHIRI D,et al.Graphene reinforced metal and ceramic matrix composites: A review[J].International Materials Reviews,2016,62(5):241-302.

[55] HUANG X, YIN Z Y, WU S X, et al. Graphene-based materials:Synthesis,characterization, properties, and applications[J].Small,2011,7(14):1876-1902.

[56] EDWARDS R S, COLEMAN K S. Graphene synthesis: Relationship to applications[J].Nanoscale,2013,5(1):38-51.

[57] WITKIN D B,LAVERNIA E J.Synthesis and mechanical behavior of nanostructured materials via cryomilling[J].Progress in Materials Science,2006,51(1):1-60.

[58] SUTHAR J,PATEL K M.Processing issues,machining,and applications of aluminum metal matrix composites[J]. Materials and Manufacturing Processes,2017,33(5):499-527.

[59] RAMANATHAN A, KRISHNAN P K, MURALIRAJA R. A review on the production of metal matrix composites through stir casting-furnace design,properties,challenges,and research opportunities[J].Journal of Manufacturing Processes, 2019,42:213-245.

[60] DONG M Q,ZHOU W W,KAMATA K,et al.Microstructure and mechanical property of graphene oxide/AlSi10Mg composites fabricated by laser additive manufacturing[J].Materials Characterization,2020,170:110678.

[61] ZHOU W W,DONG M Q,ZHOU Z X,et al.In situ formation of uniformly dispersed Al4C3 nanorods during additive manufacturing of graphene oxide/Al mixed powders[J].Carbon,2019,141:67-75.

[62] TIWARI J K, MANDAL A, SATHISH N, et al. Investigation of porosity, microstructure and mechanical properties of additively manufactured graphene reinforced AlSi10Mg composite[J]. Additive Manufacturing,2020,33:101095.

[63] ZHAO Z Y, BAI P K, MISRA R D K, et al. AlSi10Mg alloy nanocomposites reinforced with aluminum-coated graphene: Selective laser melting,interfacial microstructure and property analysis[J].Journal of Alloys and Compounds,2019,792:203-214.

[64] WANG Y C, SHI J, LU S Q, et al. Investigation of porosity and mechanical properties of graphene nanoplatelets-reinforced Al-Si10Mg by selective laser melting[J].Journal of Micro and Nano-Manufacturing,2018,6(1):010902.

[65] WU L Y,ZHAO Z Y,BAI P K,et al.Wear resistance of graphene nano-platelets(GNPs)reinforced AlSi10Mg matrix composite prepared by SLM[J].Applied Surface Science,2020,503:144156.

[66] GUIDERDONI C,PAVLENKO E,TURQ V,et al.The preparation of carbon nanotube(CNT)/copper composites and the effect of the number of CNT walls on their hardness,friction and wear properties[J].Carbon,2013,58:185-197.

[67] SAVALANI M M,NG C C,LI Q H,et al.In situ formation of titanium carbide using titanium and carbon-nanotube powders by laser cladding[J]. Applied Surface Science, 2012, 258(7):3173-3177.

[68] MASANTA M, SHARIFF S M, ROY CHOUDHURY A. Evaluation of modulus of elasticity,nano-hardness and fracture toughness of TiB2-TiC-Al2O3 composite coating developed by SHS and laser cladding[J].Materials Science and Engineering:A,2011,528(16-17):5327-5335.

[69] BASKARAN S,SELVAN B M M,ANANDAKRISHNAN V,et al.Effect of heat treatment on wear behavior of hot extruded AA7075-4%TiC in situ metal matrix composite[J].Applied Mechanics and Materials,2014,541-542:263-267.

[70] PANDEY U,PUROHIT R,AGARWAL P,et al.Effect of TiC particles on the mechanical properties of aluminium alloy metal matrix composites(MMCs)[J].Materials Today:Proceedings,2017,4(4):5452-5460.

[71] SUI Y W,CHEN X,WANG R,et al.Wear behavior of in-situ TiC particles reinforced aluminum matrix composite[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2017, 32:552-556.

[72] GENG R, QIU F, JIANG Q-C. Reinforcement in Al matrix composites:A review of strengthening behavior of nano-sized particles[J].Advanced Engineering Materials,2018,20(9):1701089.

[73] PANDEY U,PUROHIT R,AGARWAL P,et al.Study of fabrication, testing and characterization of Al/TiC metal matrix composites through different processing techniques [J]. Materials Today:Proceedings,2018,5(2):4106-4117.

[74] AKINWAMIDE S O,ABE B T,AKINRIBIDE O J,et al. Characterization of microstructure, mechanical properties and corrosion response of aluminium-based composites fabricated via casting-a review [J]. The International Journal of Advanced Manufacturing Technology,2020,109(3-4):975-991.

[75] FAN Z J,LI C,YANG H L,et al.Effects of TiC nanoparticle inoculation on the hot-tearing cracks and grain refinement of additively-manufactured AA2024 Al alloys [J]. Journal of Materials Research and Technology,2022,19:194-207.

[76] 贾增庆,高通,王桂龙,等. 激光选区熔化2024 改性AlSi10Mg合金[J].中国有色金属学报,2022,32(11):3257-3267.JIA Z Q, GAO T, WANG G L, et al. Selective laser melting of 2024-modified AlSi10Mg alloy[J].The Chinese Journal of Nonferrous Metals,2022,32(11):3257-3267.

[77] WANG Y C, SHI J. Effect of hot isostatic pressing on nanoparticles reinforced AlSi10Mg produced by selective laser melting[J].Materials Science and Engineering:A,2020,788:139570.

[78] ZHOU Y,WEN S F,WANG C,et al.Effect of TiC content on the Al-15Si alloy processed by selective laser melting: Microstructure and mechanical properties[J]. Optics & Laser Technology, 2019,120:105719.

[79] GU D D,WANG H Q,DAI D H,et al.Densification behavior,microstructure evolution,and wear property of TiC nanoparticle reinforced AlSi10Mg bulk-form nanocomposites prepared by selective laser melting[J].Journal of Laser Applications,2015,27:S17003.

[80] TAN Q Y, YIN Y, FAN Z Q, et al. Uncovering the roles of LaB6-nanoparticle inoculant in the AlSi10Mg alloy fabricated via selective laser melting[J].Materials Science and Engineering: A,2021,800:140365.

[81] MAIR P,GOETTGENS V S,RAINER T,et al.Laser powder bed fusion of nano-CaB6 decorated 2024 aluminum alloy[J].Journal of Alloys and Compounds,2021,863:158714.

[82] SHINKARYOV A S, OZHERELKOV D Y, PELEVIN I A, et al.Laser fusion of aluminum powder coated with diamond particles via selective laser melting: Powder preparation and synthesis description[J].Coatings,2021,11(10):1219.

[83] XUE G, KE L D, LIAO H L, et al. Effect of SiC particle size on densification behavior and mechanical properties of SiCp/Al-Si10Mg composites fabricated by laser powder bed fusion[J].Journal of Alloys and Compounds,2020,845:156260.

[84] XUE G,KE L D,ZHU H H,et al.Influence of processing parameters on selective laser melted SiCp/AlSi10Mg composites: Densification,microstructure and mechanical properties[J].Materials Science and Engineering:A,2019,764:138155.

[85] WANG M,SONG B,WEI Q S,et al.Improved mechanical properties of AlSi7Mg/nano-SiCp composites fabricated by selective laser melting[J].Journal of Alloys and Compounds,2019,810:151926.

[86] YI J C, ZHANG X W, RAO J H, et al. In-situ chemical reaction mechanism and non-equilibrium microstructural evolution of(TiB2+TiC)/AlSi10Mg composites prepared by SLM-CS processing[J].Journal of Alloys and Compounds,2021,857:157553.

[87] CHANG F, Gu D D, DAI D H, et al. Selective laser melting of in-situ Al4SiC4+SiC hybrid reinforced Al matrix composites:Influence of starting SiC particle size[J].Surface and Coatings Technology,2015,272:15-24.

[88] DAI D H, GU D D, XIA M J, et al. Melt spreading behavior, microstructure evolution and wear resistance of selective laser melting additive manufactured AlN/AlSi10Mg nanocomposite[J]. Surface and Coatings Technology,2018,349:279-288.

[89] DAI D H,GU D D,POPRAWE R,et al.Influence of additive multilayer feature on thermodynamics,stress and microstructure development during laser 3D printing of aluminum-based material[J].Science Bulletin,2017,62(11):779-787.

[90] LI X W, LI G, ZHANG M X, et al. Novel approach to additively manufacture high-strength Al alloys by laser powder bed fusion through addition of hybrid grain refiners [J].Additive Manufacturing,2021,48:102400.

[91] HE P D,LIU Q,KRUZIC J J,et al.Machine-learning assisted additive manufacturing of a TiCN reinforced AlSi10Mg composite with tailorable mechanical properties [J]. Materials Letters, 2022,307:131018.

[92] MIAO K, ZHOU H, GAO Y P, et al. Laser powder-bed-fusion of Si3N4 reinforced AlSi10Mg composites: Processing, mechanical properties and strengthening mechanisms[J]. Materials Science and Engineering:A,2021,825:141874.

[93] KONOPATSKY A S, KVASHNIN D G, CORTHAY S, et al. Microstructure evolution during AlSi10Mg molten alloy/BN mi croflake interactions in metal matrix composites obtained through 3D printing[J].Journal of Alloys and Compounds, 2021,859:157765.

[94] MARCHESE G, AVERSA A, LORUSSO M, et al. Development and characterisation of aluminium matrix nanocomposites Al-Si10Mg/MgAl2O4 by laser powder bed fusion[J].Metals,2018,8(3):175.